One is surprised at the casual approach to rooftop safety in the Indian PV industry.

With the emerging boom in the residential rooftop solar market, there are a number of entrepreneurs leaping into the marketplace. Unfortunately, most of them are untrained on a skilled execution of rooftop solar. And a large percentage of them are not even aware of the hazards of working the rooftop – or the standard operating procedures to follow to build occupation safety for themselves and for their workers.

In fact, even the training programs being conducted by government backed MSME bodies are casual in their coverage of the worker safety

The OSHA standards and LOTO procedures from the global programs can be brought to the Indian context and the solar PV sector. I have focused on the same in the rooftop solar PV national occupation standards – as a key skill set to take our national solar skill standards to the global level!

We need to learn from the global experience. The number of fatalities relating to Rooftop are scary. And , in the Indian context, I do not think the issue is the cost of the safety procedures. I estimate it to be less than Rs.200/- per kw on a costing of Rs.38000/- per kw overall cost! The real issue is lack of awareness of the hazards, a professional approach to mitigating the risks and lack of skill standards.

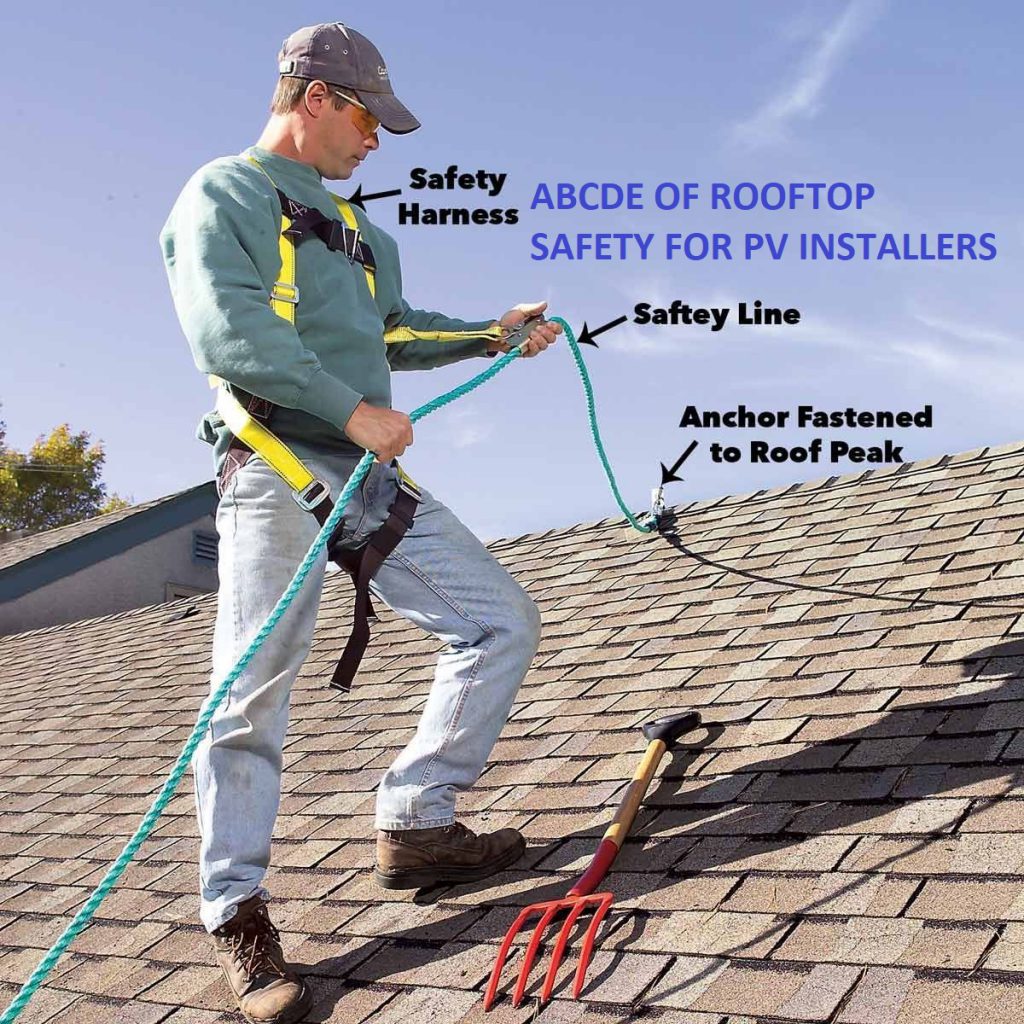

Let me summarize the ABCDE of PV rooftop safety.

A- Anchorage is critical for enabling the workmen to move safely on the rooftop. It should be identified and prepared carefully so that in the event of a fall, the anchor can support the force generated by the workman’s fall. This is typically at an OSHA standard of 5000 lb force.

B- Body Harness connects to the anchorage and life-lines. It has to be of appropriate quality and should be worn just right. Too tight,too loose, too long… are danger flags. And a safety harness that has been exposed to a fall has to be taken out of service – not reused!

C- Cables and connectors are the life-lines for the workmen. They have to be appropriately selected. The kernmantle static ropes are recommended for the rooftop work. The type of fibre that is used in the rope, the usage of the rope, the type of knots that are used in the ropes are all critical in determining the actual life of the rope and actual force that the rope can withstand. Operating conditions can dramatically reduce the actual effective strength of the lifeline and its life! Use of carbiners and grips to secure the life lines and workmen are critical skills in PV rooftop safety -and I don’t see that being taught to the aspirants in the field. Being brave here without the hazard consciousness is just being foolish.

D- Deceleration mechanisms in the event of a fall can prevent fatalities and body injuries.

E- Emergency procedures can make all the difference in preventing fall trauma and even fatalities.

It is critical that the supervisor has a proper safety training – it is his task to identify potential hazards, mitigation options, keeping relevant logs, establishing the discipline and safety procedures in his group!

As a nation, we have set an ambitious target of 40 GW of rooftop solar by 2022 in the National Solar Mission. Even though we are lagging behind the targets, we have crossed ~5GW of rooftop solar at a very high CAGR of nearly 60%. In short, we are having a potential market of 1 million installations of 5KW (average residential rooftop size) every 5GW of residential rooftop installations. As shared in my PhD thesis, it is critical that the systems are seen as working as per expectations, with least effort in enabling the same thru a qualified, well-trained solar system integrator base that executes to international standards and workmanship with zero accidents!

This is the vision of the ESSCI solar NOS committee – a world class Solar System Integration skill program that covers industry grade,world class competence building for our future technicians – that enables them in India and abroad!